Indoor Use - Water Based - Environmentally Friendly - Non-Toxic

Quick Drying - Low Odour - Lightfast - Easy Brush Clean

Drying Time

Touch dry in approximately 2 hours.

Please note: this is an approximate drying time. There could be a number of factors that may affect this.

Coverage

Approx. coverage of 10-12m² per litre, for one liberal coat.

Littlefair's wood dyes are lovingly bottled by hand in the North West of England using the unique colour formulae created by Mr. Littlefair himself.

We bring you a unique formula that penetrates the wood to produce a beautiful aged appearance on timber such as furniture, doors, skirting boards, architraves, mouldings and floors.

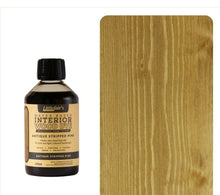

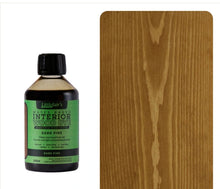

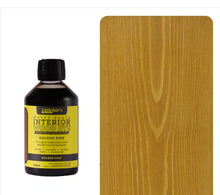

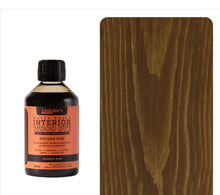

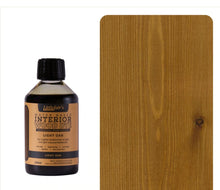

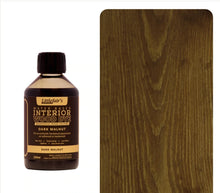

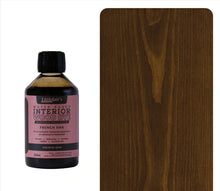

Our Antique Stripped Pine will create an authentic 'old stripped pine' effect, Dark Pine will create a warm and mellow colour, Golden Pine, Light Oak & Light Rosewood will create a warm, more modern shade, whilst Black Ebony, Brown Mahogany, Dark Red Mahogany, Very Red Mahogany, Dark Walnut, English Oak, French Oak, Golden Oak & Medium Oak will create an authentic hardwood colour.

Littlefair's wood dye produces the more natural 'positive' grain effect. Most other wood stains are more easily absorbed into the softer areas of the wood between the darker details of the natural grain. This results in the 'negative' stain effect as it causes the softer area to go darker which in turn leads the actual grain appearing lighter. Littlefair's wood stain enhances the darker details of the natural wood grain and produces the desired natural finish.

Colour Reproduction

We endeavour to reproduce our colours and finishes as accurately as possible - both online and in print. However there are a range of factors to consider when comparing our samples to your chosen project: the type and condition of the surface itself may produce a slightly different appearance of the finished colour. Please bear in mind the shape, size and lighting conditions.

Interior Wood Dye - Traditional Wood Colours are for indoor use only.

Mr. Littlefair's Top Tip

To help create a fine finish you could raise the grain before the final sanding. Start by dampening the wood with a thin film of water. Once dry, a final sanding will restore the flatness ready for applying the dye.

PREPARATION

Careful, thorough preparation will result in a far superior finish.

Ensure your wood is as clean as possible and free from previous finishes. Do not apply the dye to wet surfaces. Well sanded wood will be far more receptive to dye, and this will form the basis for a good quality finish. Avoid cleaning the wood with white spirit!

Upturn and shake well for a few moments prior to use, ensuring any sediment is well mixed and the colour of the liquid is consistent throughout the entire bottle. Repeat prior to each use of the dye.

To help create a fine finish you could raise the grain before the final sanding. Start by dampening the wood with a thin film of water. Once dry, a final sanding will restore the flatness ready for applying

APPLICATION

Apply the dye liberally along the grain with a good quality brush, alternatively the dye can be sprayed.

Please note that each dye may require a different number of coats depending on the shade you desire. Further coats will deepen the shade if required.

We recommend using protective gloves and splash goggles during use and simply wash out your brush with cold water afterwards.

COMPLETION

Once dry, the dyed wood can be finished with a variety of finishing products depending on the desired result.

Our Extra Strong Varnishes or Superior Worktop and Danish Oils will provide greater protection. Once the varnish or oil is completely dry, you can apply wax polish to create a durable yet softer, silky feel. Our Extra Strong Varnishes are quick drying and non-yellowing - ideal for producing a tough furniture finish on most wooden items.

The oils will be more suitable in damp conditions however to achieve a tough waterproof coating, Littlefair’s Titan Topcoat can be used for superior robust protection.

It’s important to note that the final appearance will be a combination of the natural colour of your wood, the effect of the dye and the finishing product if used. With this in mind - always produce a test piece so you can properly judge the result.